Description

Features and Applications

Austenitic stainless steel welding wire that has a low carbon content, which reduces the possibilities of inter-granular carbide precipitation.

ER 308LSi welding wire is used to weld base metals of a similar chemical composition such as 304, 305 and 347 etc.

Increased silicon content promotes weld pool fluidity to give a smooth deposit appearance.

Ideal for applications requiring atmospheric corrosion resistance typically in urban and rural media’s.

Good mechanical strength at sub-zero temperatures down to -196°C.

Precision layer wound for superior wire feeding characteristics.

Typically used on a wide range of applications including pipe work, plate fabrication and vessel production etc.

Test Certificates available

Typical Base Materials

| W.Nr: | 1.4306, 1.4301, 1.4541, 1.4550, 1.4311, 1.4546, 1.4312, 1.4300, 1.4312, 1.4371, 1.4541, 1.4543, 1.4550, 1.4452* |

| DIN: | X2CrNi 19 11 (TP), X4CrNi 18 10 (TP), X6CrNiTi 18 10 (TP), X6CrNiNb 18 10 (TP), X2CrNiN 18 10 (TP), X5CrNiNb 18 10, G-X10CrNi 18 8 (TP)* |

| AISI: | 202, 302, 304L, 304, 305, 321, 347, 304 LN, ASTM A320 Grade B8C/D, 302* |

* Illustrative, not exhaustive list

| Standards |

| EN ISO 14343-A – G 19 9 LSi |

| AWS A5.9 – ER 308LSi |

| Chemical Composition % (Typical) | ||||||

| C% | Mn% | Si% | S% | P% | ||

| 0.023 | 1.86 | 0.89 | 0.001 | 0.025 | ||

| Ni% | Cr% | Mo% | Cu% | |||

| 9.30 | 19.68 | 0.027 | 0.041 | |||

| Mechanical Properties |

||

| Tensile Strength | ≥510 MPa | |

| Yield Strength | ≥320 MPa | |

| Elongation | ≥25 % | |

| Impact Strength | ≥80 J | |

Mechanical properties are approximate and may vary based on the heat, shielding gas, welding parameters and other factors.

| Welding Parameters – M12 | ||

| Ømm | Current (A) | Voltage (V) |

| 0.80 mm | 40-120 | 15-20 |

| 1.00 mm | 80-160 | 16-22 |

| 1.20 mm | 100-210 | 17-23 |

| Welding Parameters – M13 | ||

| Ømm | Current (A) | Voltage (V) |

| 0.80 mm | 160-210 | 24-28 |

| 1.00 mm | 180-280 | 25-30 |

| 1.20 mm | 200-300 | 26-32 |

Shielding Gases

EN ISO 14175 – M12, M13

Welding Positions

EN ISO 6947 – PA, PB, PC, PD, PE, PF

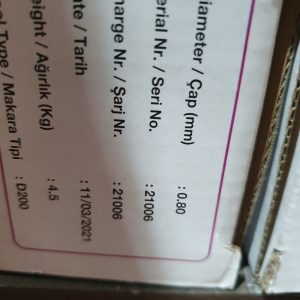

| Packaging Data | |||

| Diameter |

Weight | Spool | |

| 0.60 mm

1.80 mm 1.00 mm 1.20 mm |

5 Kg

5 Kg 5 Kg 5 Kg |

D200

D200 D200 D200 |

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained, this information is subject to change without notice and can be only considered as suitable for general guidance.

Reviews

There are no reviews yet.