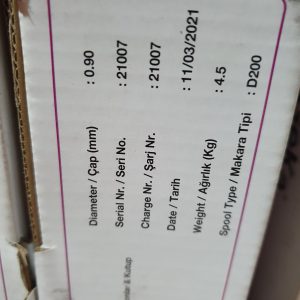

Description

Features and Applications

Copper coated high alloy solid wire for hardfacing and overlay of all C-Mn steels.

This alloy deposits a martensitic structured weld metal with a hardness of about 54-60 HRC.

Excellent abrasion resistance to moderate impact and high toughness.

The weld metal has a Cr-Si structure and if not tempered can only be machined by grinding.

Mostly used with semiautomatic and automatic procedures.

A buffer layer is essential with hard to weld steels.

Precision layer wound for superior wire feeding characteristics.

Typically used on excavators in the mining industry, cylinder crushers, pneumatic hammers, knives, cutting and cold working tools, crumbling jaws, anvils, caterpillars, screws, guide rollers, etc.

Test Certificates Available

Typical Base Materials

X45CrSi9-3, 4Xr9Si2, X45CrSi8, HNV1, HNV2, SUH11, X45CrSi 9-3, 401 S45, SUH 1, STR 1, 40Ch9S2*

* Illustrative, not exhaustive list

| Standards |

| EN ISO 14700 – S Fe 8 |

| DIN 8555 – MSG 6-GZ-60-GP |

| Chemical Composition % (Typical) | ||||||

| C% | Mn% | Si% | S% | |||

| 0.46 | <0.60 | 3.05 | <0.030 | |||

| Cu% | P% | Ni% | Cr% | |||

| <0.25 | <0.040 | <0.50 | 9.10 | |||

Mechanical Properties

Hardness (HRC) – 54 – 60

Mechanical properties are approximate and may vary based on the heat, shielding gas, welding parameters and other factors.

Shielding Gases

EN ISO 14175 – M21

Welding Positions

EN ISO 6947 – PA, PB, PC, PD, PE, PF

Reviews

There are no reviews yet.